Medmark Technology carries out Medical Gas Systems Projects from the design stage to assembly, testing and commissioning.

We provide services in all of these processes or at the desired stages, according to the demand.

The hospital's needs, budget and HTM - 02-01 standards are taken into account in the design of Medical Gas System Projects.

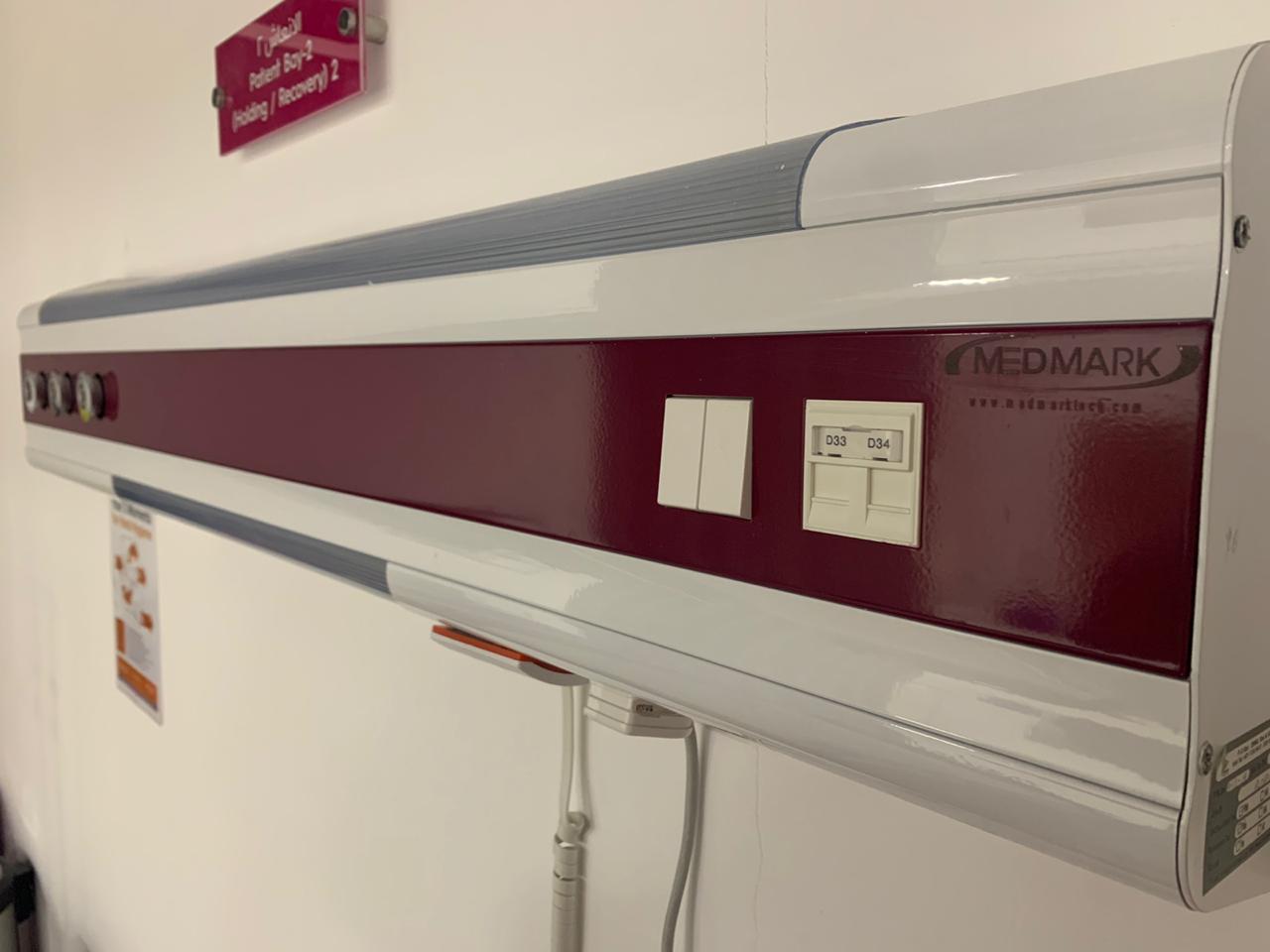

The medical gas system equipment consists of, medical gas stations (manifolds), Vacuum Pumps, Medical AIr Compressors, Area Valve Supply Units, Lockable Line Valves, Pendants, Bed Head Units and Medical Gas Outlets.

Either a small clinic or a day case surgery center or a new hospital or a renovation/ expansion in a current hospital, Medmark Technology, is making the planning in taken into consideration of major Medical Gas System requirements.

The first step in planning is the calculation of gas consumption. While making this calculation, of course, the calculation is made according to the medical engineering, but this calculation should be made by taking into account the specific conditions of the hospital. In addition, possible future expansions (such as increasing the number of beds, ICU units, operating rooms) should be taken into account, and necessary calculations should be made for gas supply.

According to these calculations, all equipment to be located in the medical gas room such as central gas stations, vacuum pump, air plant, and the type of bed head units and pendants to be used in the rooms and other necessary areas and, the locations of the AVSUs are determined.

While calculating gas consumption, the amount and diameter of the copper pipe to be used in the system are also determined. When requested, Medmark Technology also provides the installation of the entire medical gas system or assigns a supervisor to accompany the installation.