Operating Rooms: The Center of the Innovations in Hospitals

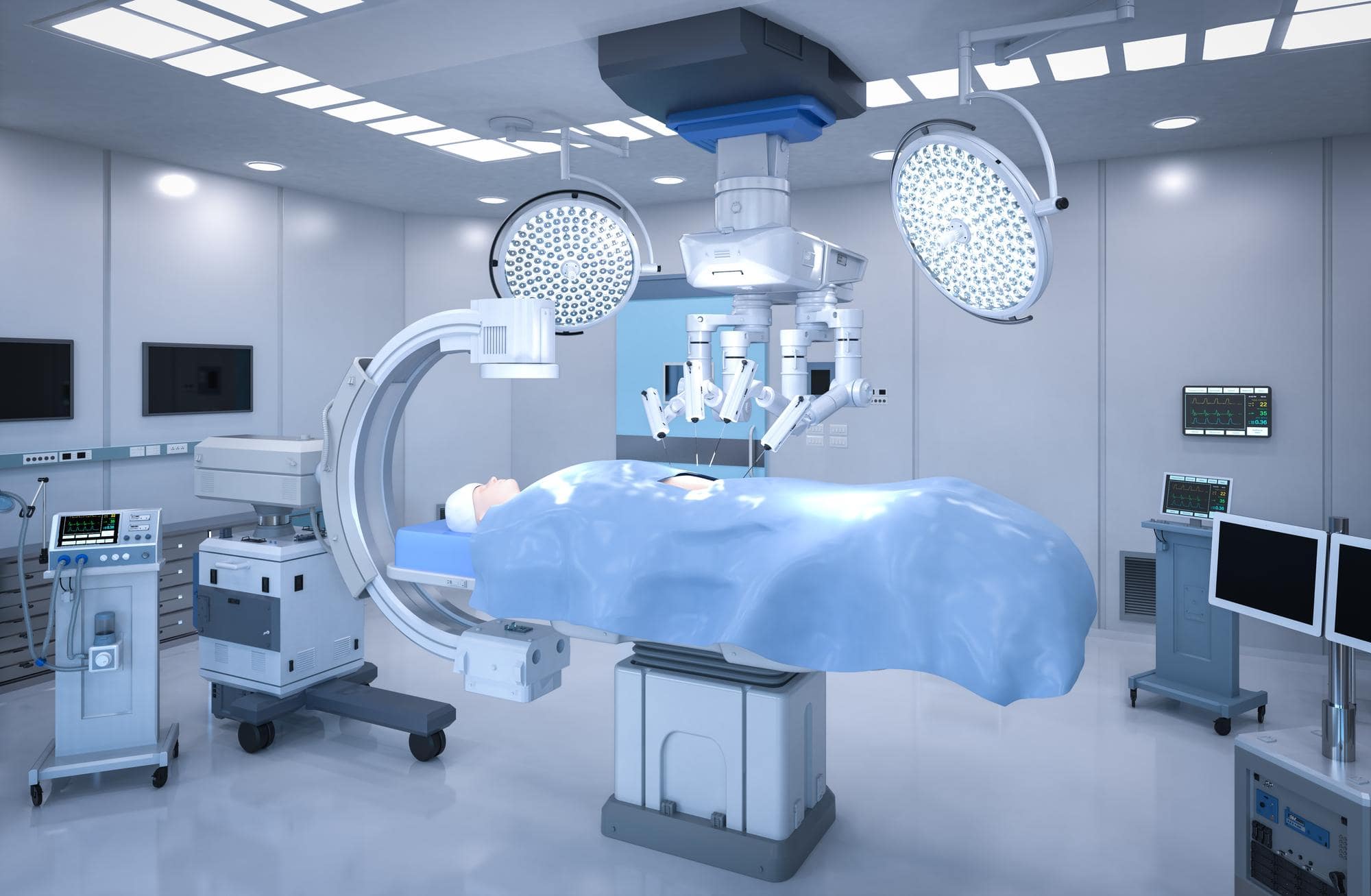

Operating rooms are the places where the reflections of technological developments are seen most rapidly in hospitals.

Modular, Hybrid, Digital Operating Rooms, Robotic Assistants have all started to become widespread as a result of these rapid reflections.

The most important goals of all these innovations are to get positive results from surgical operations and to simplify and speed up the operating room processes and workflows by keeping safety in mind.

Modular Operating Rooms, among these innovations we mentioned, have come to the fore even more in the last 5 years with their two basic features among all their advantages. These are ease of cleaning and maintenance and quick renewal.

The time spent on renovating and maintaining the existing operating theaters of hospitals or constructing new operating rooms constitutes a significant cost. Although the establishment of reinforced concrete operating rooms takes time, they are processes that require special workmanship.

Modular operating rooms are structures with fewer workers, quick installation and more cleanliness than reinforced concrete structures.

The infrastructure in which the wall and ceiling elements are mounted, connected and sealed is the skeleton of the modular operating room architecture. Profiled floor rails, vertical supports, and roof rails form the infrastructure and create spaces for other services (such as electricity and gases) to pass. Because of this infrastructure, no walls or partitions are required to set up modular operating theaters.

The surfaces of both stainless steel and glass panels used in modular operating room panels are microscopically flat and non-porous. Resistant to living organisms, chemicals and most common hospital detergents and disinfectants. Fire, noise and x-ray protection can be integrated according to project requirements. However, some features may differ from Stainless Steel to glass. In fact, aesthetics and functionality go together in glass material. Glass is a tough material with fewer joints and is fully resistant to acids and bases. On the other hand, stainless steel panels provide future-proof flexibility for service, maintenance or modernization because the wall elements can be disassembled without damage and can be designed to include a service panel that goes around the room.